Wakesurfing is an exhilarating sport, but even top-of-the-line boards aren’t immune to wear and tear over time.

Knowing how a wakesurf board is built, especially the epoxy and fiberglass layers, can help you spot cracks early and determine when repairs are necessary.

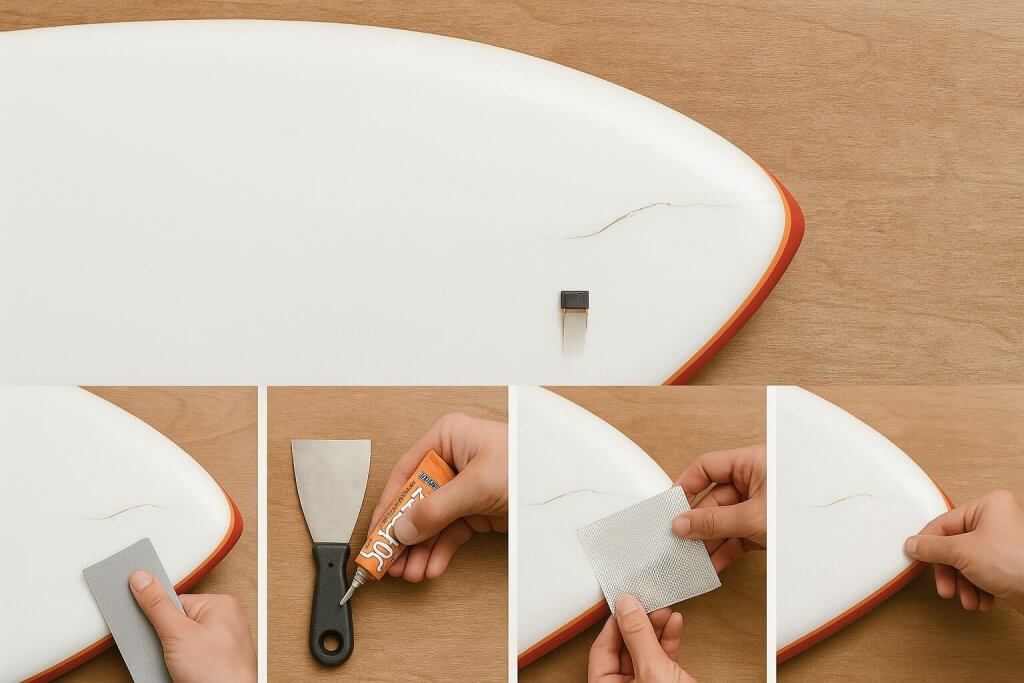

This guide breaks down the materials used in wakesurf boards, shows you how to detect damage, and provides step-by-step instructions for fixing your board at home.

You’ll also find practical tips to prevent future wear, keeping your board in top shape for years of rides.

Whether you’re a seasoned rider or just getting started, this guide will help you care for your board and get the most out of every session on the water.

Key Takeaways:

- Understanding the construction of your wakesurf board and its materials is crucial for determining if it can be repaired at home.

- Identifying signs of damage, such as cracks, is important in preventing further damage and determining if a repair is necessary.

- Repairing a cracked wakesurf board at home is possible with the right tools, such as sandpaper and a putty knife, and appropriate materials. Following step-by-step instructions can help ensure a successful repair.

Understanding Wakesurf Board Construction

A comprehensive understanding of wakesurf board construction is vital for the maintenance and repair of this equipment, ensuring it remains watertight and performs optimally on the water.

Wakesurf boards are generally composed of various materials, including fiberglass, epoxy, and microballoons, each offering distinct properties that enhance the board’s overall performance and durability.

By familiarizing oneself with these components, individuals can significantly improve their ability to identify potential issues and execute effective maintenance, thereby prolonging the lifespan of the wakesurf board.

Materials and Components

The primary materials utilized in the construction of wakesurf boards include epoxy, fiberglass, plywood, and microballoons, all of which collectively enhance the board’s strength and buoyancy.

Epoxy functions as a lightweight yet durable resin that effectively bonds these materials, thereby improving the overall flexibility and longevity of the board. Fiberglass cloth contributes additional strength and rigidity, enabling the board to endure rigorous use on the water while preserving its shape over time.

Conversely, microballoons are incorporated to minimize weight without compromising structural integrity, thereby enhancing buoyancy and overall performance.

Additionally, plywood may be integrated into the core to provide a robust foundation, which further enhances flexibility and responsiveness. Collectively, these components work in harmony to produce a high-quality wakesurf board that satisfies the requirements of both novice and experienced riders.

How to Identify a Cracked Wakesurf Board

Identifying a cracked wakesurf board is essential for ensuring safety and optimal performance during water sessions.

Common indicators of damage include visible cracks, soft spots, and delamination, all of which can compromise the board’s structural integrity and its capacity to endure the demands of surfing.

Conducting regular inspections of your wakesurf board is advisable to identify these issues early on, enabling timely repairs and the implementation of effective maintenance strategies to maintain the board in optimal condition.

Signs of Damage

Signs of damage on a wakesurf board may present as visible cracks, soft spots, or delamination, each indicating varying degrees of loss in structural integrity. Using a heat gun can assist in identifying delamination areas.

These issues arise from impacts or prolonged exposure to environmental conditions. For example, a crack on the surface may suggest that water could infiltrate the board, leading to further deterioration and compromising its performance.

Soft spots can result in uneven buoyancy, which may negatively affect the rider’s control and safety while on the water. Delamination indicates a significant separation of the board’s layers, subsequently reducing its overall functionality.

Neglecting these signs can lead to rapidly escalating repair costs and may ultimately result in the board becoming unusable. This highlights the importance of conducting regular inspections and implementing proactive maintenance measures to prolong the board’s lifespan and enhance the overall riding experience.

Repairing a Cracked Wakesurf Board at Home

Repairing a cracked wakesurf board at home is an achievable process that can result in significant savings in both time and money. With the appropriate tools and materials, including epoxy, fiberglass cloth, and sandpaper, one can effectively address dings and cracks, thereby restoring the board to its original condition.

This do-it-yourself repair process not only prolongs the lifespan of the wakesurf board but also deepens the individual’s understanding of its construction and maintenance requirements.

Essential Tools and Materials for Repair

To effectively repair a cracked wakesurf board, it is necessary to utilize specific tools and materials, including epoxy, sandpaper, and a putty knife for application.

A mixing stick is essential for thoroughly combining the epoxy components, thereby ensuring a strong bond. Additionally, a clamp or weight can be employed to apply pressure during the curing process. It is also advisable to have painter’s tape available, which will protect areas surrounding the repair site from excess epoxy. It is important to follow the manufacturer’s mixing instructions to ensure optimal results.

Furthermore, safety precautions are of utmost importance. Wearing safety glasses will safeguard the eyes from debris, and using a dust mask is crucial to prevent inhalation of harmful particles while sanding.

By preparing these essential tools and adhering to appropriate safety measures, the repair process can be conducted more efficiently and securely.

Step-by-Step Instructions

The step-by-step repair process for a cracked wakesurf board encompasses several essential steps, including thorough cleaning, epoxy application, and ensuring proper curing. This meticulous approach is vital for restoring the board’s integrity and performance on the water.

- First, it is imperative to begin by thoroughly cleaning the damaged area, removing any dirt, debris, and residual old resin.

- A light sanding with fine-grit sandpaper or a sanding disk should be conducted to create a rough surface, which will enhance adhesion.

- Once the area is adequately prepared, the next critical step is the application of epoxy.

- It is essential to carefully follow the manufacturer’s instructions for mixing the epoxy resin, ensuring an even application that completely fills the crack.

- After the application, allowing sufficient time for the epoxy to cure is vital, as this guarantees a solid bond.

- Once cured, a gentle sanding of the surface should be performed to achieve a smooth finish, followed by polishing to restore the board’s sleek, glossy appearance.

Regular inspections following the repair can assist in identifying any potential issues at an early stage, especially using safety glasses and a dust mask for protection. Regular inspections should be done even if no repairs are visible to promote proactive maintenance.

Tips for Preventing Future Damage

Preventing future damage to a wakesurf board is crucial for preserving its performance and longevity. By implementing effective maintenance practices and proper handling techniques, one can significantly mitigate the risk of dings and cracks that may arise during use or storage.

Key strategies include:

- Ensuring that the board is stored in a location shielded from UV rays,

- Avoiding harsh impacts,

- Utilizing appropriate protective gear during transportation,

- Avoid leaving the board in wet conditions.

Best Practices for Proper Handling and Storage

Proper handling and storage of a wakesurf board are essential for preventing damage and ensuring its longevity.

By following a few straightforward best practices, one can effectively safeguard the board from potential issues such as delamination, fading, and warping. It is crucial to store the wakesurf board in a cool, dry environment, away from direct sunlight, as prolonged exposure can degrade the materials over time.

Utilizing protective bags specifically designed for wakesurf equipment adds an extra layer of protection, shielding the board from scratches and impacts during transportation. Furthermore, avoiding the placement of heavy weights on the board is vital for maintaining its shape and integrity, thereby allowing for many enjoyable sessions on the water. For those looking to optimize their rides, consider exploring the best wakesurf boards for larger riders to ensure you have the right equipment tailored to your needs.

Importance of Regular Maintenance and Inspections

Regular maintenance and inspections are essential for maintaining your wakesurf board in optimal condition and avoiding costly repairs in the future.

To ensure both longevity and performance, it is advisable to conduct inspections at least once a month or following heavy use. Particular attention should be given to critical areas such as the fins, nose, and tail, as well as the overall surface for any dents or scratches.

These areas are susceptible to wear and tear; therefore, monitoring them can significantly impact the board’s performance.

Utilizing maintenance products, such as repair kits, can help address minor issues before they develop into more significant problems, providing peace of mind and ensuring that the board remains clean and in excellent condition throughout the season.

Explore our range of maintenance products today!

Bruce Paulson is the owner of PaddleboardSurf and an avid water sports enthusiast with a lifelong passion for all things aquatic. From stand-up paddleboarding and surfing to boating, kayaking, and canoeing, he thrives on the joy of being on the water. As an advocate for water conservation and environmental stewardship, Bruce shares his adventures and insights through his writing, inspiring others to embrace the beauty and excitement of life on the water.